The role of a stretch wrapping machine in industrial automation

The role of a stretch wrapping machine in industrial automation

Blog Article

Discover the Advantages of Using a stretch wrapping machine for Efficient Product Packaging Solutions

In the globe of product packaging options, performance is key. Automation has actually generated substantial developments, such as the stretch wrapping machine. With its capacity to cover things firmly and rapidly using stretchable plastic film, it supplies a high degree of accuracy and speed. It's not almost wrapping items, yet also concerning reducing labor prices, minimizing waste, and preserving aesthetic charm. What makes these makers a game-changer in the packaging sector?

Understanding the Functionality of Stretch Covering Machines

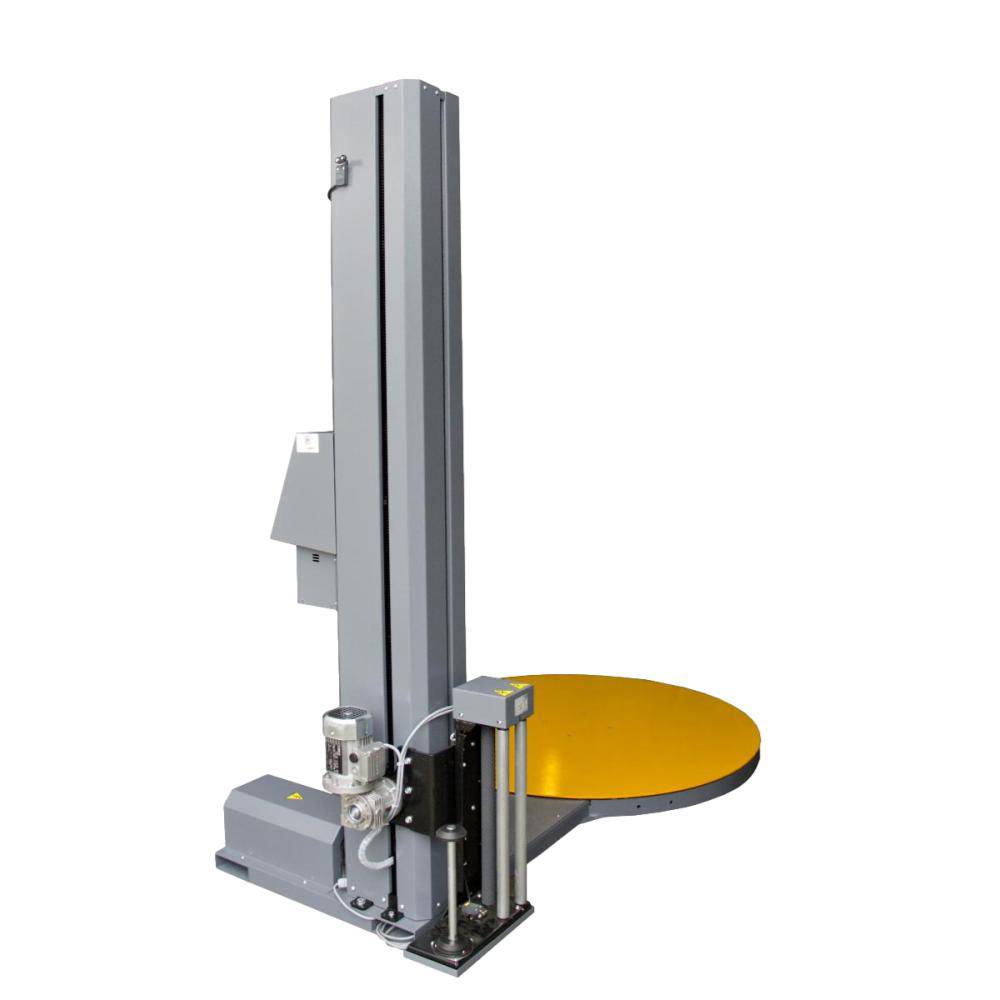

Pioneering the product packaging industry, stretch wrapping devices improve the procedure of securely product packaging products for transportation or storage. These advanced machines employ a basic yet reliable device, making use of a stretchable plastic movie that is covered around things, giving stability and security. The items, typically set up on a pallet, are revolved as the film is dispensed, guaranteeing a secure and tight cover.

The film's flexibility serves a twin function: it snugly binds the items with each other, reducing the threat of damage because of motion, and it supplies a barrier against dirt, moisture, and various other prospective harmful components. The transparent nature of the stretch film enables for simple identification of the packaged things.

The devices vary in their operation setting, with some being semi-automatic, requiring very little human intervention, and others being totally automated, efficient in individually taking care of the entire covering procedure. Despite their mode, stretch wrapping machines are a keystone of effective and safe packaging.

Exactly How Stretch Wrapping Machines Enhance Productivity

Improving performance levels significantly, stretch wrapping equipments simplify the packaging procedure with their automated abilities. These innovative devices make it possible for companies to cover a high volume of packages quickly and effectively, delivering a consistent covering outcome that hand-operated techniques simply can not match. This speed and consistency translate straight into enhanced efficiency, making it possible for companies to meet requiring supply routines and client assumptions.

Moreover, stretch covering devices require very little human intervention. As soon as the equipment is established and the covering criteria are set up, the maker can operate individually, freeing up workers to focus on various other vital jobs. This automation not only minimizes labor expenses yet likewise eliminates human mistakes, guaranteeing the quality of wrapping continues to be regular.

Additionally, using stretch covering machines often brings about less downtime. stretch wrapping machine. With their robust layout and trusted operation, these equipments are much less vulnerable to breakdowns and maintenance concerns, ensuring continuous process and boosted performance

Minimizing Product Waste With Stretch Covering Machines

While enhancing efficiency, stretch covering equipments likewise play a vital function in minimizing material waste. The accuracy of these Bonuses makers ensures that each plan is wrapped with the specific quantity of material required, minimizing excess waste. This accuracy not just leads to a cosmetically pleasing and consistent plan, but also adds significantly to environmental sustainability.

Essentially, the utilization of stretch wrapping machines in a product packaging line is not only an action towards efficient performance, however additionally a leap towards green practices by considerably decreasing product waste.

Expense Reduction: A Trick Benefit of Stretch Wrapping Machines

Along with mitigating material waste, another substantial benefit of stretch wrapping makers is their potential for stretch wrapping machine cost reduction. These machines are reliable, needing much less manual work for product packaging products, therefore lowering labor prices.

Furthermore, stretch covering devices use less product to package goods securely as compared to typical wrapping methods. This effective usage of materials not just reduces waste yet also lowers expense on product packaging products.

The makers also lessen damage to products throughout transport. With sturdy and safe and secure packaging, the risk of product damage reductions, reducing the expenses related to item returns and replacements.

Ultimately, the rate and effectiveness of stretch covering machines can raise manufacturing rates. Faster packaging times suggest that companies can package and deliver more products in much less time, improving general efficiency.

Executing Stretch Wrapping Machines in Your Product Packaging Refine

Given the remarkable advantages of stretch wrapping equipments, including them right into your product packaging process can be a game-changing decision. An evaluation of the existing product packaging process is needed to figure out the optimal equipment kind and size.

Training staff on maker operation is essential. This includes comprehending the maker's performances, repairing typical concerns, and sticking to security standards. By doing so, businesses can guarantee an effective, affordable product packaging procedure, reaping the complete advantages of their investment in stretch wrapping devices.

Verdict

In verdict, stretch wrapping makers provide reliable, cost-efficient product packaging solutions. These devices guarantee item stability and defense, while likewise delivering visually pleasing packages.

When the machine is established up and the wrapping specifications are configured, the equipment can run independently, freeing up staff members to concentrate on other critical jobs.While boosting performance, stretch wrapping equipments likewise play a crucial duty in minimizing material waste.Offered the remarkable benefits of stretch covering devices, integrating them right into your packaging process can be a game-changing decision - stretch wrapping machine. By doing so, businesses can guarantee an effective, cost-effective packaging process, reaping the complete benefits of navigate to these guys their investment in stretch covering equipments

In conclusion, stretch wrapping devices offer reliable, cost-effective product packaging services.

Report this page